Die changing carts RW are manually moved.The die changing table is equipped with ball inserts which facilitate the manual insertion of the dies. During the transport, the ball

Die changing carts RW are manually moved.The die changing table is equipped with ball inserts which facilitate the manual insertion of the dies. During the transport, the ball

Get Instant Quotation for FDM, SLA, SLS, MJF, DMLS/Metal 3D Printing Services in Bangalore, Mumbai, Mysore, Chennai + (91) 96067-70777. Get Injection Mold tooling uses aluminum or steel inserts to make the tool. This method is only for small quantities up to 10,000,000 pieces. Injection Molding yields the lowest per-part cost.

Using resin bins in a plastic injection molding plant can immediately help with material control and cleanliness. Resin bins are a perfect solution to health and safety regulations controlling the manual lifting of heavy loads such as bags of raw material.

Nov 17, 2020 · ICOMold’s interactive online quotation system is unique and revolutionary – a game-changer when it comes to quick time-to-market for your custom plastic

Single Station Scissors Lift Mold Cart This 3,500 pound capacity Model LDC single station, end payoff cart transfers molds to/from storage racks and multiple injection molding machines. Dual Station Scissors Lift Mold Cart This lift die cart can handle two 10,000 pound dies. Both die stations have gravity conveyors and powered mold transfer.

Sep 01, 2019 · A new low-pressure injection molding process has aroCustom interest among molders and machine suppliers. In his second article on iMFLUX, the inventor of the process explains how it is evolving to support the overall industry goal of self-correcting molding

Online Quotation & Order To become / upgrade to a Corporate User, you will need to set up an Perfectunt with MISUMI. Kindly click on Registration Form (Open in a new window) and follow the instructions on 'User Registration' page to complete and submit the online form.

Powered Die Transfer Carts. Atlas has been a pioneer in die change technology. We have become an industry leader in heavy andPerfect powered die transfer cart based floor

Aug 17, 2020 · How to select a China plastic mold vendor; Procedures for Developing a New Plastic Product; What should we need for quotation; Glossary Plastic Injection Moulding; Plastic Mould Design Tutorial; Cooling Time Calculation of Injection Molding; Injection Molding

Transfer Ladles, Sow Molds Metal Pumps, Shredders, Ingot Molds, Preheaters . Tooling DME Unit Holders Shot Sleeves, If you are finished you can request your quotations by clicking on the Request Quotation Now button. Request Quote Now. You have no items in your cart.

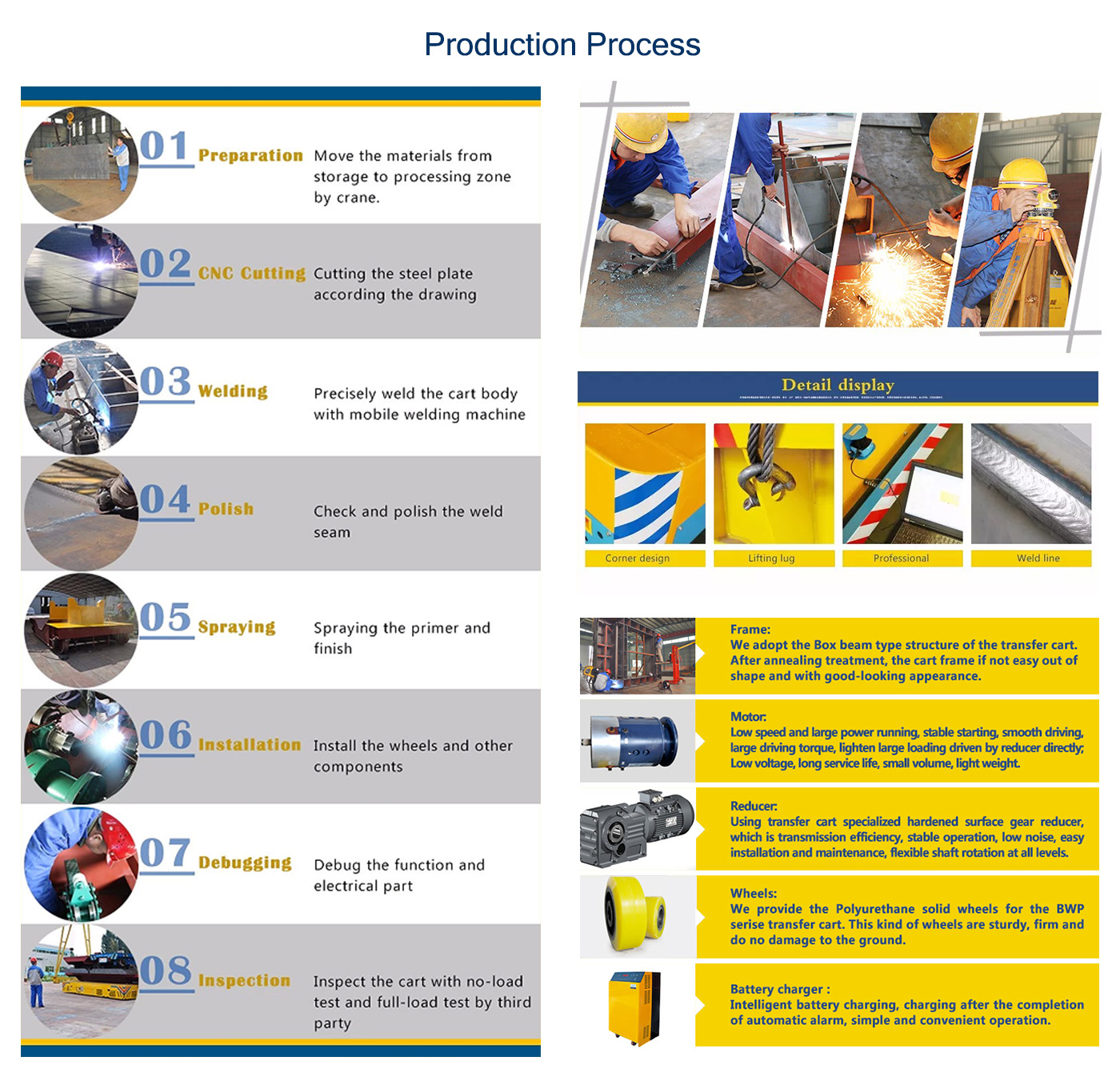

Product Introduction. The injection molding tool carts for molds is designed for die and mold handling, it is an electric transport cart which can be powered by a battery, low voltage rail, cable drum, towed cable. There are two types of electric transfer carts

Consider Aluminum and Stainless Steel: The life of an injection mold tool depends on two main factors. One being the material that the tooling is made from. Aluminum tooling is considerably cheaper than

Jingwei industry – Your High Volume, Custom Plastic Parts Injection Molding Specialist. If you need a precision high-volume molder you have come to the right place. We make billions of parts each year in our factory. We offer a turnkey manufacturing solution Perfect Steerable Transfer Cartluding mold design, mold

Fori Automation’s Rail Guided Carts (RGC’s) are a cost effective, flexible replacement for traditional conveyor systems. Develop oversea business, arrange quotation, commercial invoice, dies timing. 2. Review the strip design and SIM. ... ★Plastic Injection Mold★Mold Spare Parts★Prototyping★Stamping Molds★Rubber Molds

Feb 01, 2013 · In terms of cost estimating, in the past, before a final estimate of the total cost for a product could be put out, price quotation had to be made by the plastic injection manufacturer after the R&D firm had come up with a design for the plastic injection molding part, hence cost estimating was usually delayed, and then cost estimating was often conducted on an empirical basis which made it