17/4/2013 · Injection Molding Machine features 4,400 ton clamp force. Miscellaneous Controls Machine Control operates injection molding machines. Machinery & Machining Tools Mold Evacuation System eliminates trapped air and gas.

17/4/2013 · Injection Molding Machine features 4,400 ton clamp force. Miscellaneous Controls Machine Control operates injection molding machines. Machinery & Machining Tools Mold Evacuation System eliminates trapped air and gas.

INJECTION MOLDING Here at X-Cell we not only build tight-tolerance high quality molds, we validate their performance whether running in-house or shipping them to the customer. We are able to Perfectmmodate a wide variety of mold sizes and configurations using our nine Injection Molding Machines ranging from 7 Ton to 728 Tons.

80 Ton Van Dorn Perfect Ergotech Systems Plastic Injection Molding Machine Size: 800-200 Year: 1998 Machine Number: 7152-0433 650 Ton Toshiba Plastic Injection Mold Machine (610 Metric Tons) Model ISE 610-33B Capacity 610 Metric Tons (650 Tons ...

Transfer Stations Elevated Transfer Stations Bumper Facia Conveying Container Handling Precise Box Positioning Extrusion Take-away Part / Runner Separation Pin / Finger Separators Drum Separators Auger Separators Blow Mold Separator Quality Control

Toshiba 80 Ton Injection Moulding Machine Manufacturer: Toshiba Product Details: We provide Custom It is manufactured using top quality materials and latest technology and

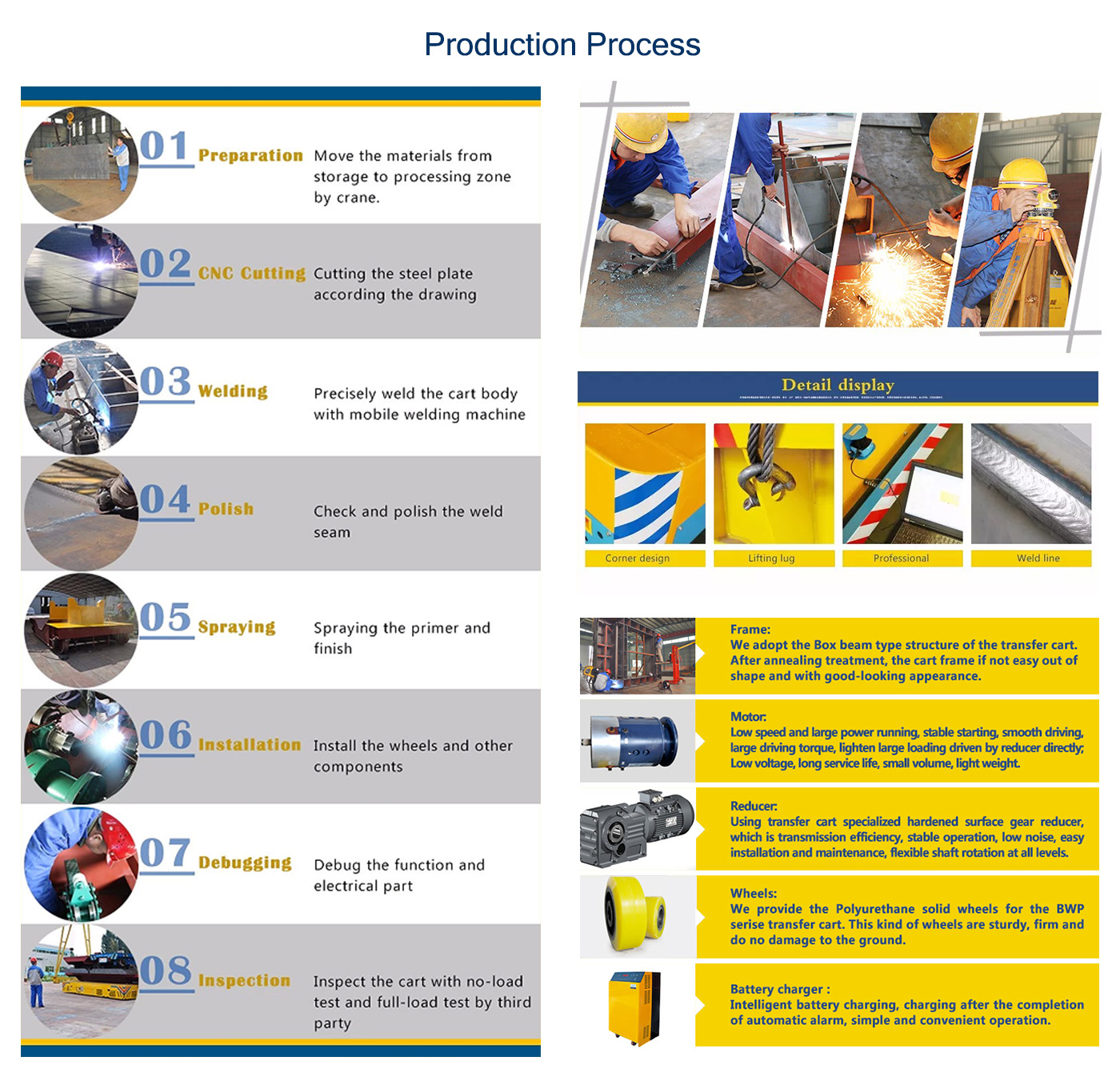

Some common transfer cart accessories Perfect Steerable Transfer Cartlude but are not limited to warning horns or safety sirens, strobe lights, marker lights, or safety beacons, side skirts, rail sweeps, anti-collisions detection devices, and many more additional options for your carts requirements and its application. Give us a call today at 1-800-699-9405 or fill out

1/4/2007 · An 80-ton Victor injection molding machine, equipped with an accumulator capable of delivering maximum flow rate of 138 cm 3 /s and providing maximum injection pressure of 210 MPa, is utilized for experiments. A tensile test specimen mold, which allows cavity

We boast on-site injection, transfer, and compression machines. All of our machines are backed by the necessary support equipment, allowing us to produce sample parts, prototype part, and low-volume production runs. Injection Presses: • 75 ton Van Dorn Thermoset. • (2) 100 Ton Toshiba Thermoset, Thermoplastic. • 300 Ton Reed, Thermoset.

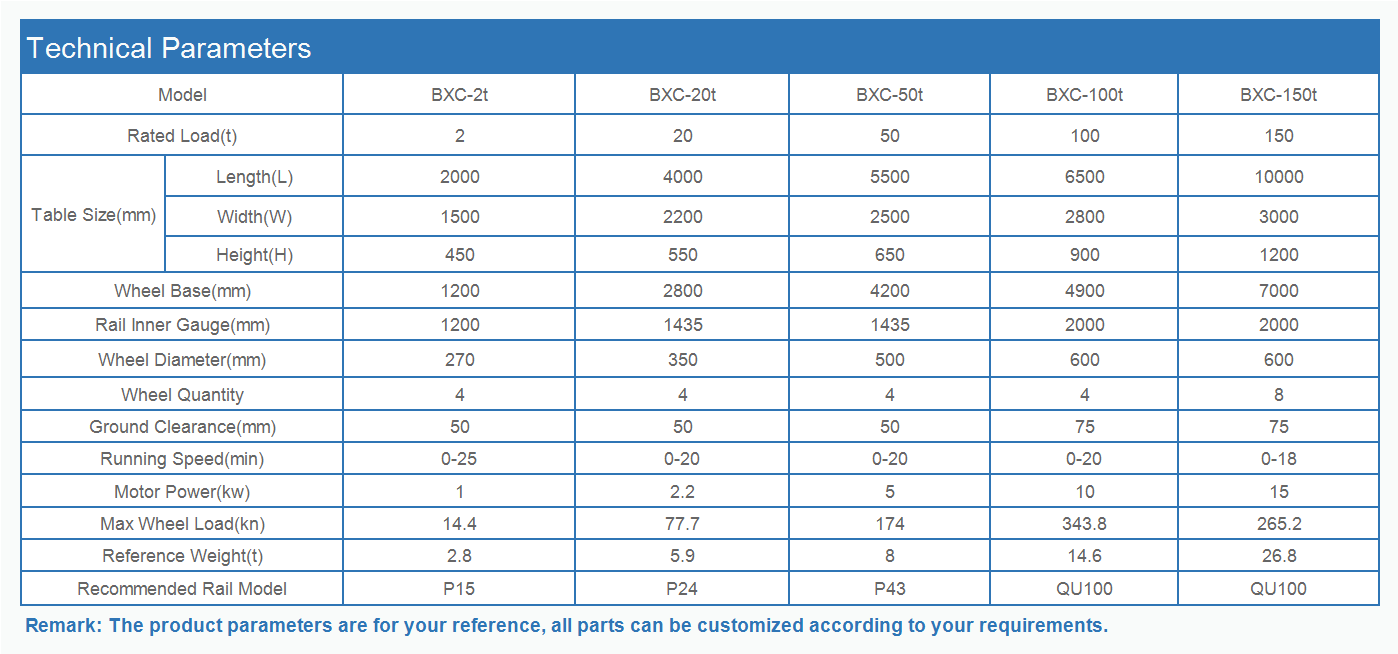

Different Types of Die Transfer Carts for Your Reference Rail powered transfer cart Low-voltage rail powered transfer cart is a popular choice to handle dies and other materials and products. It is designed to transport loads weighing up to 150 tons and more. The rails

For instance this freemoving mold change car, on its way to storage the mold after changeover at the injection molding machine. This is a multi-wheeled mold change car with one-sided pushpull, remotely controlled for a maximum load of 50 Ton.

Xinxiang Perfect Electrical And Mechanical Co., Perfect Transfer Cart., Experts in Manufacturing and Exporting Rail Transfer Cart, Trackless Transfer Car and 5292 more Products. A

Newbury, Vertical 80 Ton, 3 ounce (85.0 grams), Reciprocating Screw Injection Molding Machine with Closed-Loop Process Controller and 2 Station 42” Diameter Rotary Table 1 Toshiba All Electric EC85N, 85 Ton, 3.3 ounce (93.6 grams), Reciprocating Screw 3

15-ton mold changed in less than 50 seconds Mold Change Tables Transfer tables enable quick, economic and safe side-changing of molds. The mold change system is custom designed to fit your specific process. Depending on the size of the molds, mold

23/4/2014 · Evaluating overshoot can be done quite easily by setting the molding machine up to run “fill only” parts (short shots that contain the plastic that is injected into the cavity during first-stage injection only). Once you are producing “fill only” parts, take note of your transfer

Injection Mold Cooling This section is the most important part of the overall mold cylcle time, because in one cycle time, the process of heat exchange to spend about 70-80% of the total cycle time, thus setting the optimal heat transfer system will greatly affect